Our competence centre for process engineering develops plants from simple test benches to large-scale plants and from the initial idea to operational optimisation. We support the planning and implementation of both material and thermodynamic processes in plant design, design and component dimensioning, and simulations of individual components as well as complete plants. In addition, we design and test the control of complex systems, accompany plant construction and commissioning, and monitor operation and convert the results into operational optimisation. We always work closely with customers and project partners and transfer theoretical, scientific findings into practice.

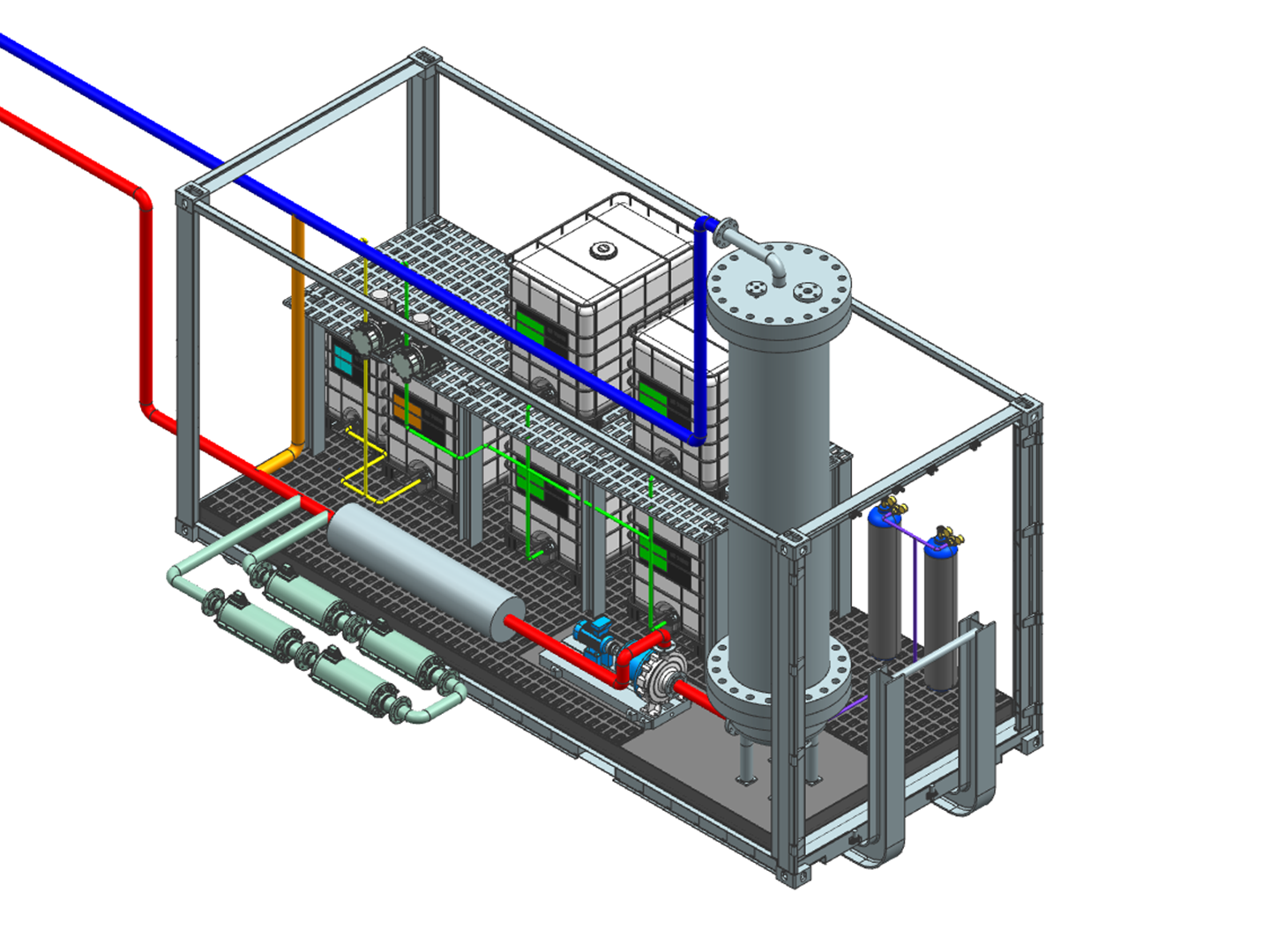

Thermal processes in industry and in neighbourhoods face the same challenge as the energy system as a whole: becoming more sustainable and integrating new energy sources. To this end, process engineers at the Fraunhofer IEG transfer scientific findings into application. Their sphere of activity covers plant construction from simple test stands to the integration of new material or thermodynamic processes in existing large-scale plants. They provide support from the initial idea to implementation: in plant design (basic engineering), plant design, component dimensioning (detail engineering), plant construction, commissioning or operational optimisation.

As an interface between science and technology, the experts at Fraunhofer IEG classify new ideas, check and evaluate their technical and economic feasibility. They develop and operate precisely fitting test plants, reproduce real plant components as well as complete plants as independent simulations in the computer and design, for example, control concepts of complex systems based on them. The industrial partners include developers and manufacturers of components and plant components, plant constructors in the fields of air conditioning, heating and basic chemicals as well as operators of thermodynamic and chemical plants.

The spectrum of technologies ranges from next-generation thermodynamic converters - such as high-temperature heat pumps and multiphase salt storage - to binary power plant processes, process engineering for water desalination and high-temperature borehole pumps for geothermal energy. Areas of application can be industrial processes, neighbourhood networks with bi-directional load management for cooling and for heating or classic district heating structures in metropolitan regions.

Process Engineering

More project references

- MissElly – Seasonal storage of heat underground for air conditioning purposes

- GECO - Construction of a reactor for the synthesis of geothermal fluids

- InnoTherm Ruhr – Strengthening and networking of geothermal actors Exploration, drilling, grid, consumers

- Erosion tests with sand - Testing of new ceramic coatings

- H2 (in steel industry, from biomass)

- Groß-TRT (Sound test facility)