Great importance is ascribed to the production of green hydrogen as a substitute for fossil resources in order to achieve the 2045 climate targets. However, around one third of the electrical energy used in hydrogen electrolysis using proton exchange membranes (PEM) is converted into waste heat. In addition, the oxygen produced during the electrolysis process remains mostly unused. In the IntegrH2ate project, Fraunhofer IEG and its project partner Linde GmbH are therefore investigating the utilization of the by-products from the hydrogen electrolysis process: heat and oxygen. The aim of the investigations is to increase the economic feasibility of the hydrogen production with PEM electrolysers. The IEG contributes to the project with its expertise in the fields of process engineering, thermodynamic converters and system integration of power plants. 4 million of the total funding of around 19 million euros will go to Fraunhofer IEG. The project is supported as part of the flagship project H2Giga by the German Federal Ministry of Research, Tecnology and Space (FMRTS). It will run for 45 months and is expected to end in September 2025.

IntegrH2ate - Investigation of the by-products heat and oxygen from PEM electrolysis systems based on theoretical and experimental studies

Goal

During PEM electrolysis, the resulting waste heat usually occurs at a temperature level of 50 to 60 °C and is therefore, without thermal upgrading, only available to a small range of applications. Through the use of (high-temperature) heat pumps, however, this heat can be used by a wide range of application fields.

The focus lies on the upgrading and utilization of this heat at a refinery site. Up to now, large-scale electrolysis plants have usually been operated in chemical parks, where numerous consumers can be considered for heat utilization. The particular challenge is to couple the dynamic operation of the electrolyser due to the variable hydrogen demand and the fluctuating availability of solar and wind power with the more inert system of the heat pump and the heat demand profile.

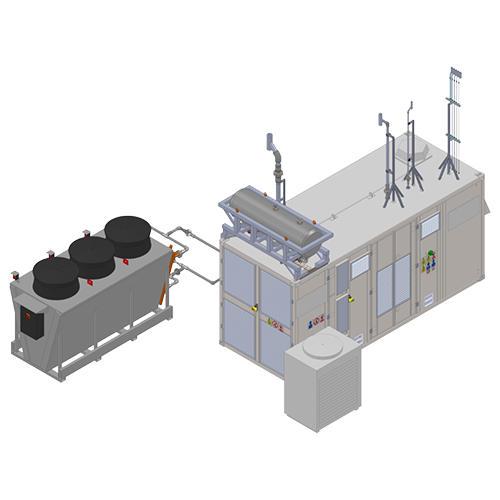

First, the recovery and upgrading of the generated waste heat is investigated with the aid of a heat pump simulation model. The optimal operating strategy and suitable system components (compressors, heat exchangers, etc.) will be determined. In the further course of the project, the simulation results will be validated by means of an experimental setup at the IEG site in Zittau. The aim is to transfer the simulative and experimental research results to a demonstration plant in the 100 MW range at a refinery site of the project partner. In addition, concepts for the upgrading and utilization of the by-product oxygen at refinery sites will be developed.