The project ‘Kabel Zero’ aims to develop a geothermally driven process steam production for the paper drying procedure in the paper mill of the Kabel Premium Pulp & Paper GmbH (KPPP) in Hagen, North Rhine-Westphalia. Deeply buried Devonian ‘Massenkalk’ carbonates potentially depict geothermal reservoirs and, thus, the source for industrially applicable hot thermal waters.

The first partial project elaborating the fundamental feasibility of the vision ‘Kabel Zero’ according to various geological studies and technical simulations and models is called ‘Geothermal paper drying’. This project started in February 2020 and is processed until the end of 2022 by the Fraunhofer IEG, the Kabel Premium Pulp & Paper GmbH and the Fraunhofer UMSICHT. While the Fraunhofer IEG takes care of geoscientific tasks, mainly dealing with subsurface issues, Fraunhofer UMSICHT develops the superficial process technology, and KPPP is the project’s lead partner responsible, amongst others, for the coordination and exchange between the partners and of relevant information. ‘Geothermal paper drying’ is funded by the ‘EFRE’ program set up by the European Union and the German state of North Rhine-Westphalia.

Geothermal paper drying - geothermal exploration and exploitation concept

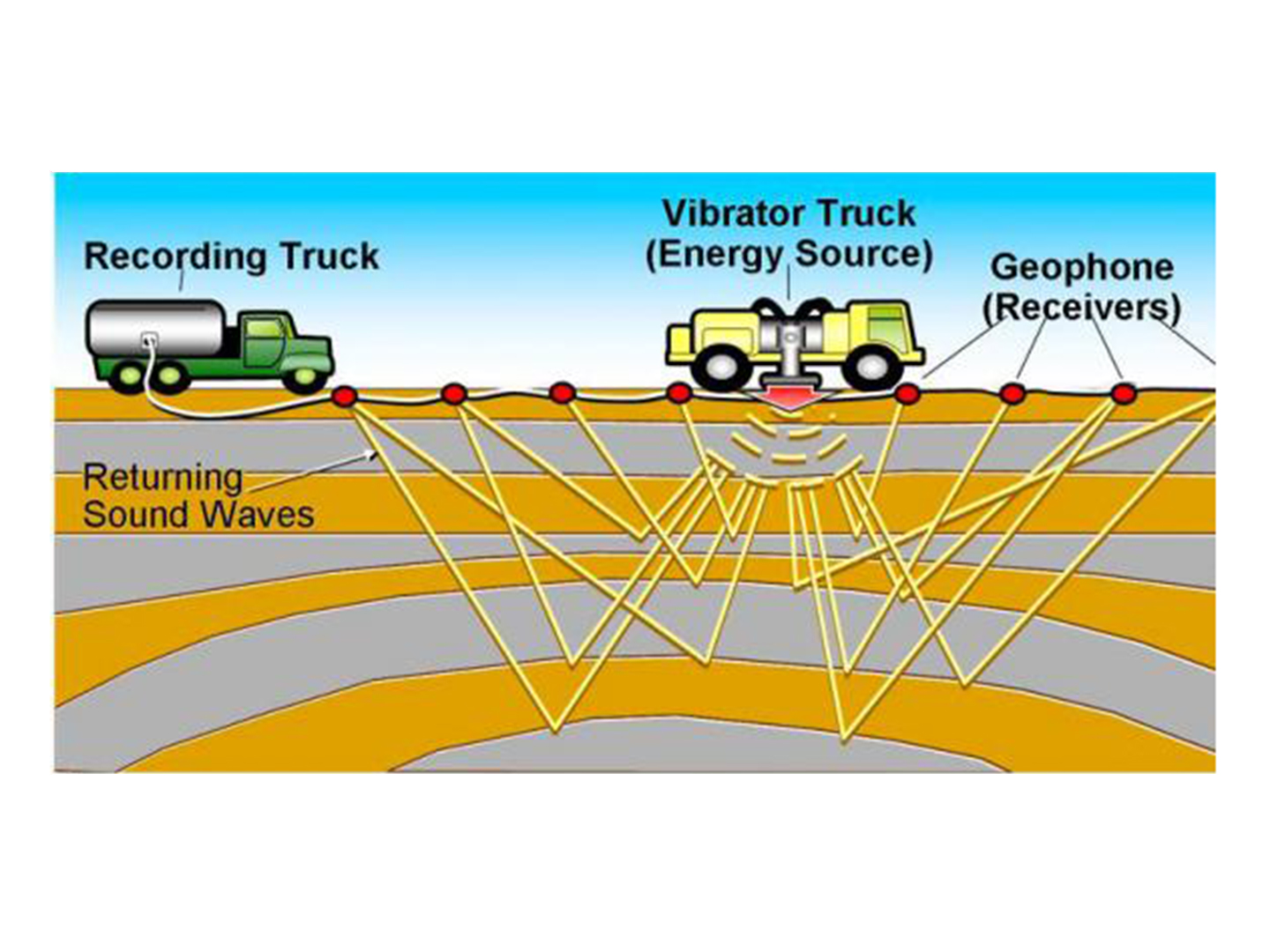

In the paper industry, large amounts of industrial process steam ranging from 100 °C to 200 °C are required for the drying process within the paper production cycle. Typically the process steam is generated in central facilities fired with fossil fuels like natural gas. To reduce the CO2 emissions associated, i.e. the ecological footprint of the whole paper production, and save fossil fuel costs long-term, the paper mill in Hagen Kabel initiated the vision ‘Kabel Zero’ in 2018. In the first step, the superordinate goal is to examine the subsurface conditions regarding the availability of geothermal reservoir formations that could be exploited economically and the elaboration of technical concepts for using naturally occurring thermal waters and transferring their thermal energy to industrial process steam. In principle, the premises of KPPP’s production site exhibit favourable conditions for installing a hydrothermal doublet system: On the one hand, the property is intersected by the so-called ‘Großholthausener Sprung’, which is a regionally important NNW-SSE striking normal fault system potentially triggering elevated hydraulic conductivities in the subsurface and, thus, an increased reservoir potential and economic viability. Secondly, Devonian carbonates are presumably located in deep geothermal reservoir depths between 2,500 and 4,100 m underneath the paper mill, according to the geological model of the Geological Survey of North Rhine-Westphalia and the results of a 2D seismic survey conducted by the DMT Group commissioned by the Fraunhofer IEG. As shown by various geothermal operations in the Munich area using hydrothermal doublet systems, carbonate rocks potentially represent suitable geological formations for deep geothermal energy supply in Germany.