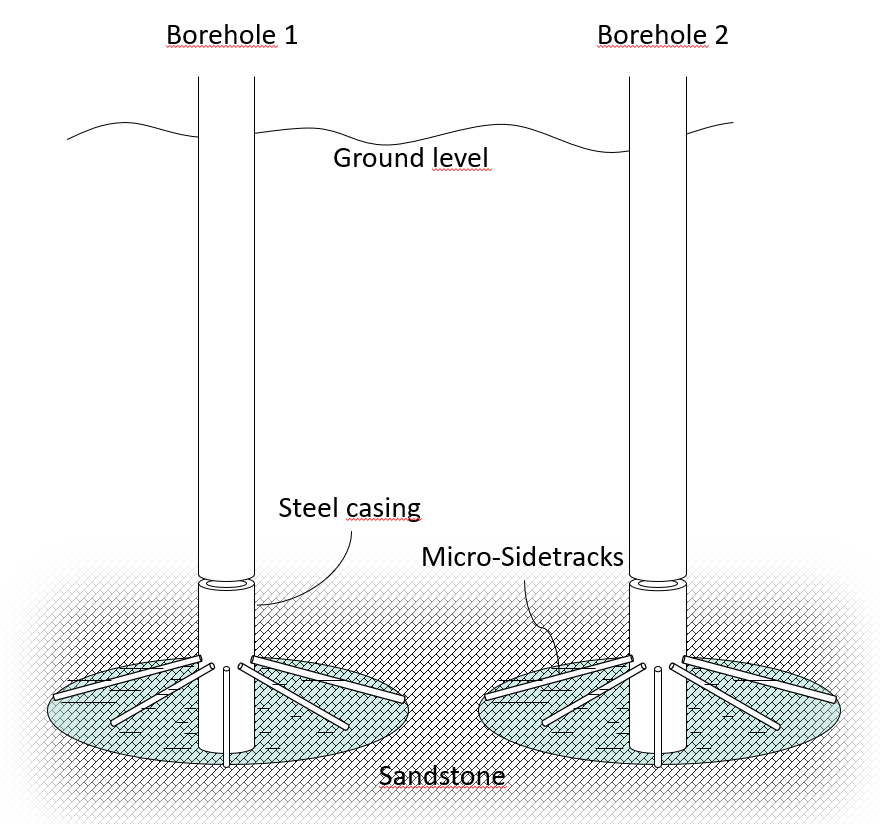

The Competence Center "Micro-drilling Technology" focuses on the development of the new drilling technology "Micro Turbine Drilling - MTD®". The fundamental motivation for MTD® comes from the field of deep drilling technology. MTD® is a mechanical drilling method for drilling sidetracks in the micro range—so-called Micro-Sidetracks (e.g., 2 inches or smaller) from an existing main borehole into the surrounding geology. Both soft sedimentary rocks and hard crystalline rocks (e.g., granite) can be drilled. It is a surgical and minimally invasive method, providing a low-risk and gentle alternative to hydraulic stimulation (fracking) without significant interventions in the geology.

How does the MTD® drilling technology work?

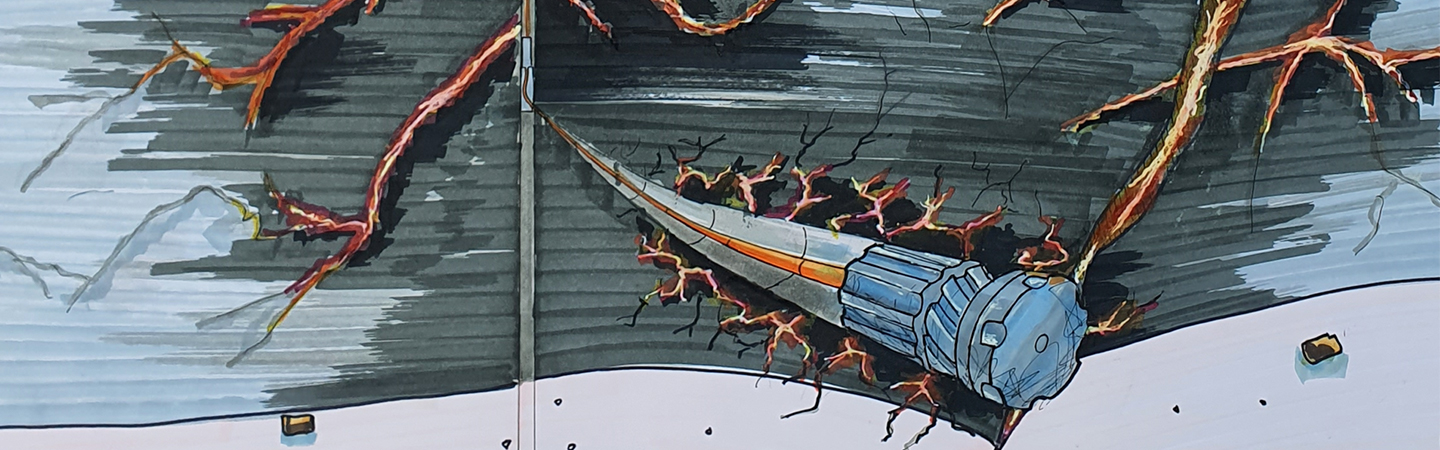

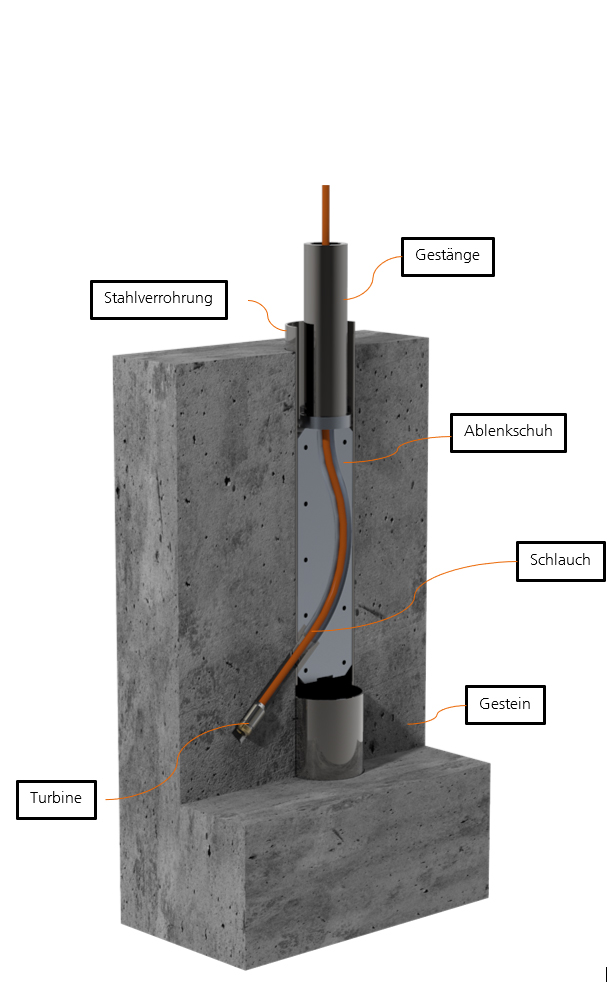

The main component of MTD® is a 1.5-inch micro-drilling turbine powered by pressurized water. Equipped with an innovative diamond drill bit, it is possible to drill various types of rock (e.g., granite, clay, sandstone) as well as steel in a single operation. When applied in a cased borehole, the drilling tool or drill bit does not need to be changed during or after the perforation of the steel casing, making it more time- and cost-efficient. To penetrate a formation with the Micro-Sidetracks, a deflection shoe is installed at the desired deflection point within the cased or uncased borehole using a deployment rod at the desired drilling depth. At this point, the kick-off direction for the Micro-Sidetrack can also be determined and set—if necessary. Subsequently, the micro-drilling turbine is run in on a flexible coiled tubing string up to the outlet of the deflection shoe, and the drilling process is initiated by pressurizing the turbine. The very compact design of the drilling tool allows for an exceptionally small deflection angle of the micro-drillings from the main borehole.