The necessary reduction of greenhouse gases poses significant challenges for all energy-intensive industries. The provision of industrial process heat is currently responsible for a large portion of CO2 emissions and often occurs in company-owned combined heat and power (CHP) systems. At the same time, significant waste heat potentials are not utilized or are only insufficiently harnessed. Heat pumps enable the temperature level of a heat source to be raised, thereby upgrading the heat for further use. Many industrial processes require process heat, for example in the form of process steam, at temperatures between 120 and 200 °C. High-temperature heat pumps can play a key role in shaping future energy systems in this temperature range as well.

Development of a high-temperature heat pump with steam screw compressor for heat and process steam supply.

For heat provision in the temperature range of common district heating networks, high-temperature heat pumps are already available and are currently being tested in various implementation projects. However, for sink temperatures above 120°C, there are only a few high-temperature heat pumps available, some of which are still in prototype status and are characterized by partially low efficiency as well as the use of climate-damaging, synthetic, or hazardous refrigerants.

The goal of the collaborative project SteamScrew is the joint development of a high-temperature heat pump using water as the refrigerant to provide heat at a temperature level of 140 to 200°C. The temperature level of the heat source ranges from 80 to 120°C and can be provided in the later application field, for example, through waste heat or deep geothermal energy.

The choice of water as the refrigerant brings various positive properties. In addition to good thermodynamic suitability, this includes aspects such as environmental compatibility, availability, the possibility of direct process steam utilization, and safety classification. However, using water as a refrigerant presents technical challenges for developers. This particularly concerns the significant temperature increase during compression, which goes far beyond the intended temperature range without cooling the refrigerant, complicating the compressor design.

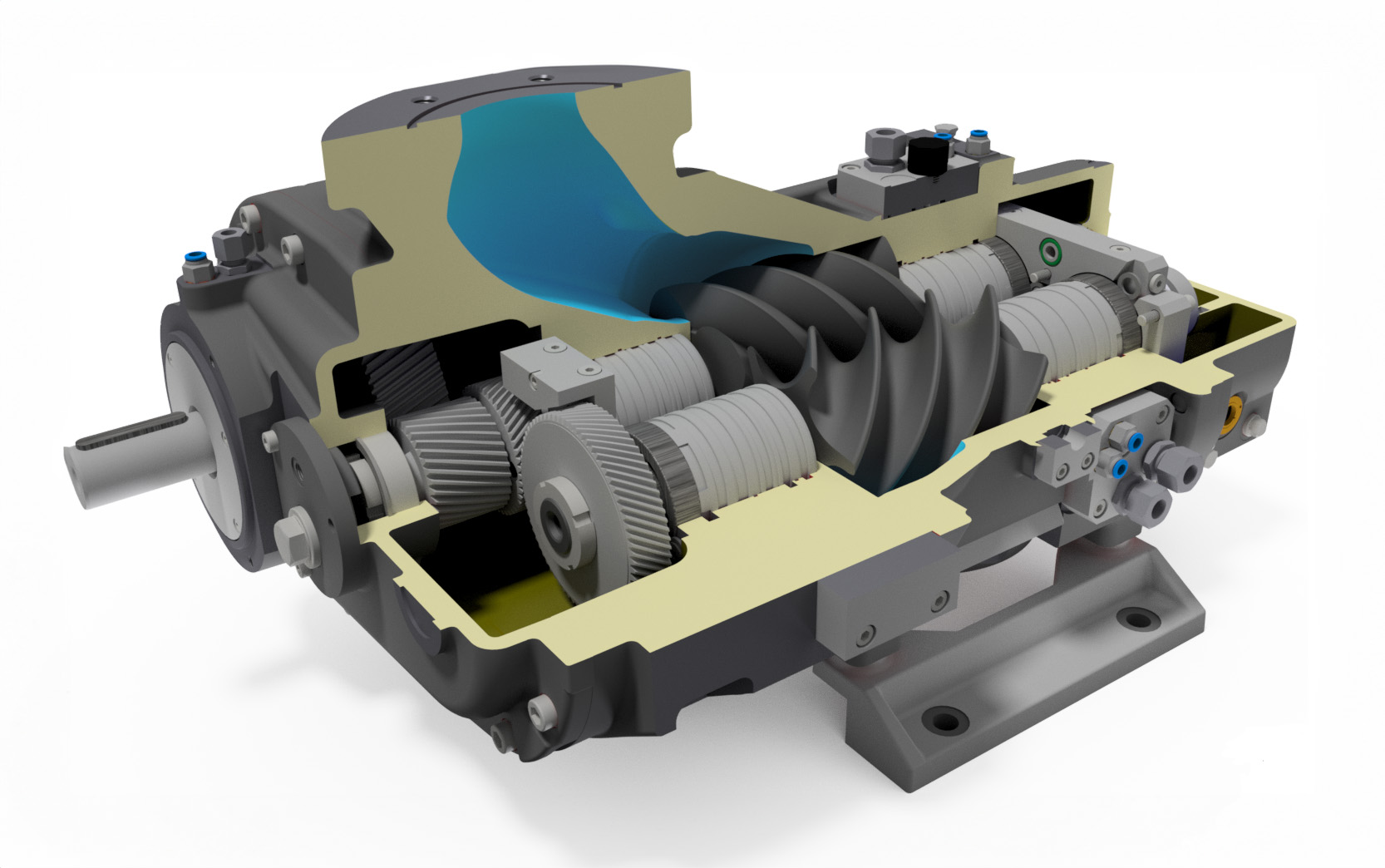

One focus of the project is therefore on enhancing a screw compressor for the targeted temperature range. Screw compressors are robust, market-leading displacement machines suitable for achieving the temperature lift in a single compression stage while simultaneously injecting liquid cooling water into the compression chamber. Accordingly, the development of an appropriate material, bearing, and sealing concept, as well as the optimization of injection parameters, are central to the compressor enhancement. Simulative and experimental results will contribute to the compressor development throughout the project, leading to gradual improvements during the project duration.

The compressor, initially tested in air and steam cycles in early experiments, will then be tested at Fraunhofer IEG in a closed heat pump circuit with approximately 400 kW thermal maximum capacity under laboratory conditions. The aim is to generate process heat at an industrial temperature and pressure level, albeit with a total capacity of the system lower than the actual industrial demand. The potential for scaling the heat pump to industrial size for future utilization is also a central aspect of the project. The experimental data obtained will be used to calibrate simulation data, allowing for the subsequent determination of the suitability, efficiency, and size of the heat pump for integration into industrial processes via simulation.

Förderung