With Plasma Pulsed Geo Drilling (PPGD), a drilling process that removes rock electrically and thermally using high-voltage pulses is currently in development. The rock is destroyed with essentially no contact, which drastically reduces the wear on the drilling tools and increases the service life of all drilling components, which is an absolutely essential factor of any drilling process. The process is especially suitable for hard, crystalline rocks, such as the rocks found in geothermal reservoirs.

PLASMA PULSED GEO DRILLING

Fraunhofer contract research for ETH Zurich in the Pulsed Plasma Geo Drilling project

Geothermal energy is always available. Compared to wind and solar power, electricity generated with geothermal energy has the advantage of being able to meet the base load, offering an alternative to coal, gas, and nuclear power. However, temperatures of at least 150°C are required in order for geothermally generated electricity to be economically viable. Such temperatures are found at depths of 5 to 10 km. The initial costs of building a well of this depth account for a major part of the total cost of geothermal systems.

Plasma pulsed geo drilling hopes to reduce the cost of drilling. The rotary drilling method that is currently used removes the rock mechanically with cutters. The components wear out quickly, especially when drilling through hard rock. To change the cutters, the entire drill string needs to be removed (tripping). This process takes a long time, during which no further drilling progress can be made. With the PPGD method, the rock is removed with virtually no contact using high-voltage pulses. This will hopefully allow wear on the drilling tools to be minimized.

The temperatures and high pressures found at depths of 5 km have a non-negligible impact on the process.

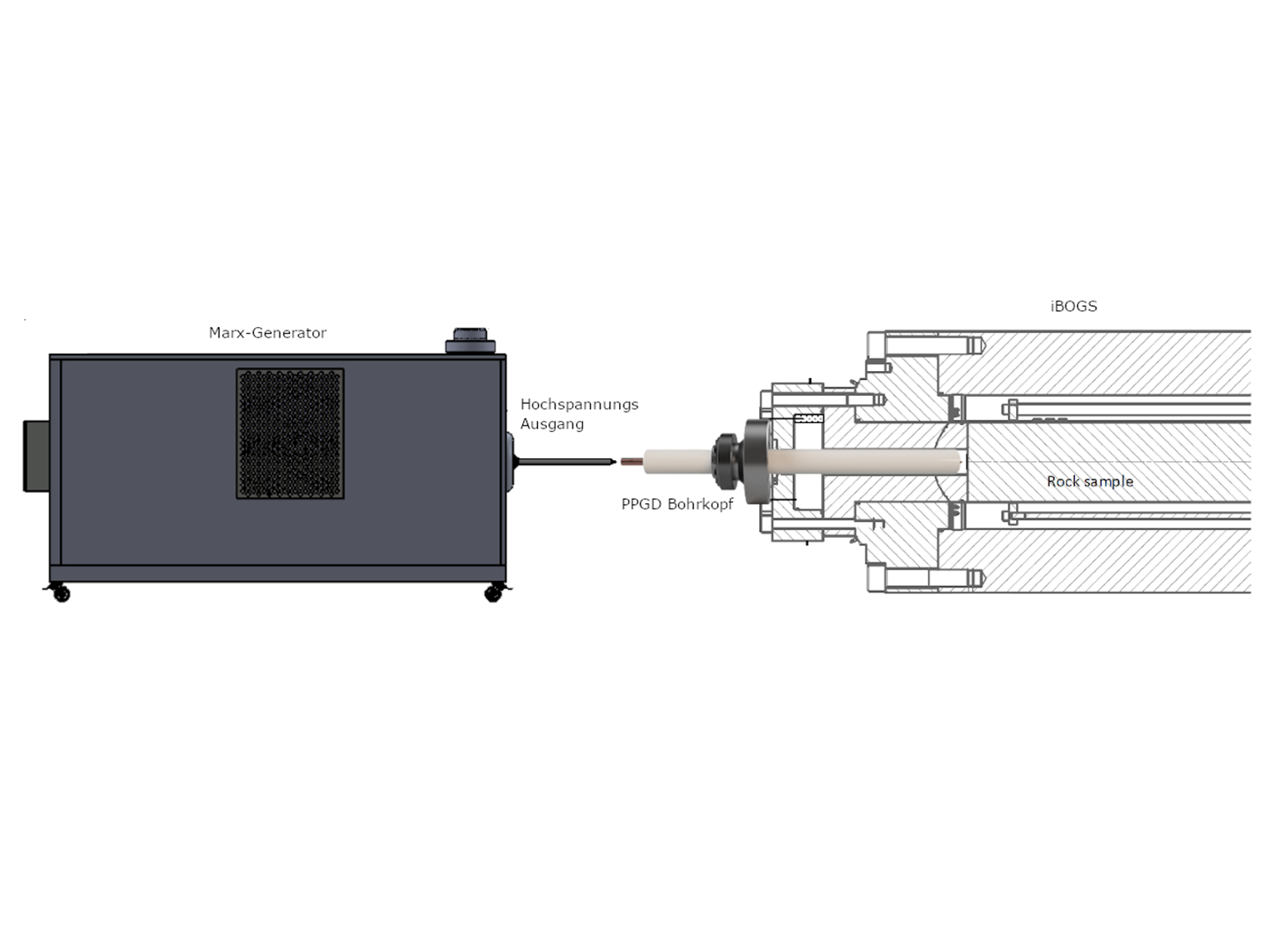

Whether PPGD can be used under high pressure and temperature conditions has not yet been studied. The iBOGS autoclave system at the Fraunhofer IEG location in Bochum allows the conditions at these depths to be simulated. Various experiments are planned in the iBOGS to collect information about the conditions at which the process still works.

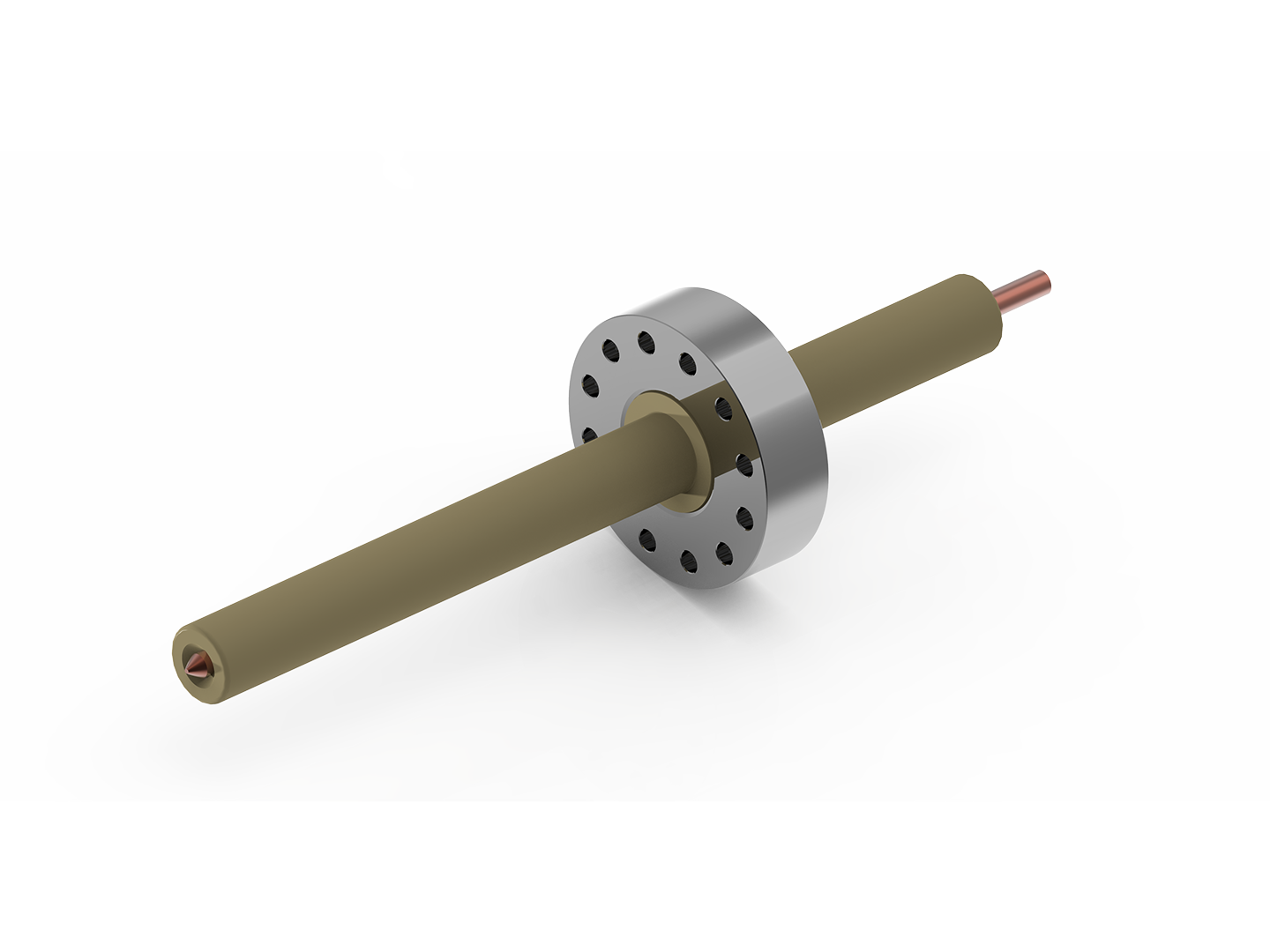

Applying the high-voltage pulses to the rock samples inside the autoclave is one of the major challenges of these experiments. A high-voltage drill head is being specially developed for this purpose. There is a high-pressure duct in the autoclave’s lid. The drill head can be fed through here.

The Marx generator generates voltage pulses of up to 450 kV. This generator is being provided on loan by ETH for the duration of the experiments.