The exploration risk for geothermal wells is high, as the desired flow rates can often not be achieved due to insufficient permeability of the rocks in production horizons. Processes are already known from the oil and gas industry that can in principle be used to increase the permeability of a reservoir. These include pressurised water-based methods (e.g. Radial Jet Drilling (RJD)), with which small-calibre deflection wells are produced from the main well in order to hydraulically connect surrounding fault zones, especially fractures, to the well. The known methods offer solutions for soft reservoir rocks that are easy to drill with conventional methods. However, these conditions, which are typical for oil and gas reservoirs, cannot simply be transferred to geothermal reservoirs. These are often formations of hard rock where the water jet technology used in the RJD process has no or too low drilling performance.

MTD® – Micro Turbine Drilling

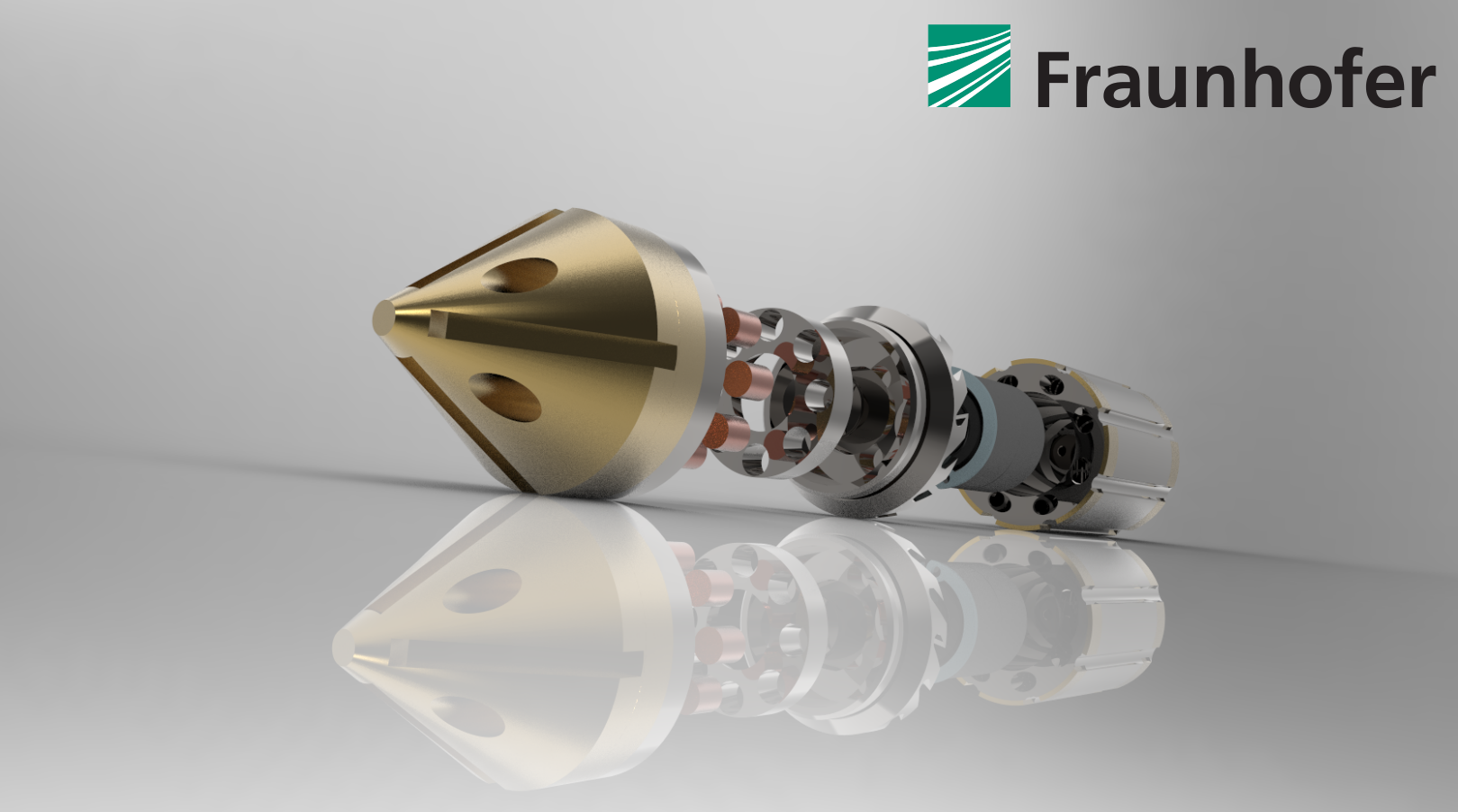

In the Micro Turbine Drilling (MTD®) project applied for here, a method is to be developed with which the permeability can be increased even in very hard production horizons of geothermal wells. The solution is based on the principle of RJD. However, no nozzle head is used, which generates the rock removal directly through an emerging fluid jet. Instead, a micro drilling turbine is used in which the hydraulic energy of the fluid is converted into mechanical energy to drive a drill bit with which the rock removal is generated mechanically. Preliminary tests carried out with functional prototypes confirm the basic functionality and thus the great potential of the technology.

The result of this project should be a new drilling method with which it is possible for the first time to produce cost-effective, at least 50 m long deflection wells from a cased borehole up to 5 km deep into hard rock formations with temperatures of up to 200 °C. The decisive advantage over the state of the art is the ability to mechanically generate rock removal. The decisive advantage over the state of the art is that this process is also suitable for use in geothermal energy and numerous other underground development measures at low cost.

The target market for the new drilling method is fluid mining. The focus is particularly on geothermal energy, including underground storage technology, but the oil and gas industry is also a potential customer. The market potential of the process is enormous due to its unique selling proposition and the expansion of geothermal energy decided by the German government in the coming years. A large number of enquiries from industry for such a process confirm this.