The reduction of atmospheric CO2 concentration is one of the major challenges of the 21st century. One of the largest emitters responsible for a significant portion of current anthropogenic CO2 emissions is the construction sector. According to the "2022 Global Status Report for Building and Construction", around 37% of global CO2 emissions came from this sector in 2021. Particularly problematic are cement-based building materials, as process-related CO2 emissions are unavoidable during their production. Therefore, these emissions must be captured and stored during the manufacturing process. An alternative approach to improving the CO2 footprint of building materials is being explored in the "FasOli" project by Fraunhofer IEG in collaboration with the building material manufacturer Knauf Gips KG.

FasOli

Objective

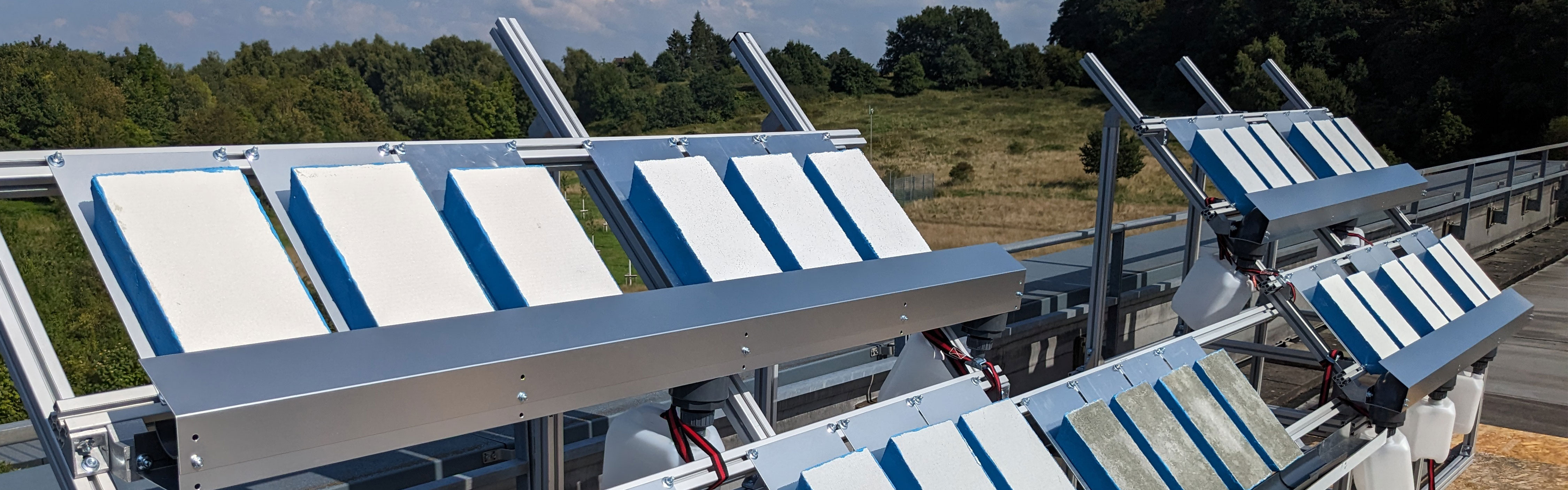

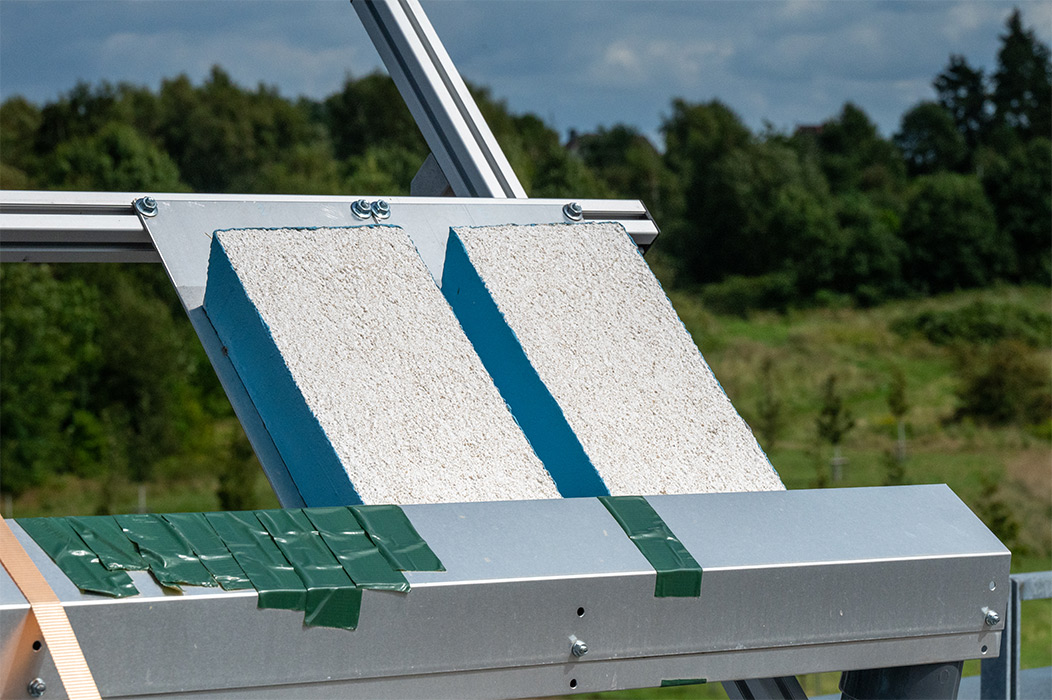

FasOli adopts the principle of "Enhanced Rock Weathering", a method that accelerates natural rock weathering by finely grinding silicate rocks and spreading them on the Earth's surface. Through the weathering of silicate minerals, the alkalinity in water is increased, allowing more atmospheric CO2 to be bound in the water. The dissolved CO2 can then combine with cations such as Ca, Mg, or Fe to form carbonate minerals, which precipitate as solids. This mechanism is now to be used to enhance the CO2 absorption capacity of building materials. To this end, Knauf has produced a facade plaster with an olivine additive, a mineral that weather rapidly and is rich in Mg and Fe. Compared to the original idea of "Enhanced Rock Weathering", incorporating olivine into building materials has the advantage of creating a marketable product. However, whether such an olivine-based facade plaster actually sequesters more CO2 from the atmosphere than conventional plaster is being tested in a long-term study at Fraunhofer IEG. A test setup with various facade plaster panels has been constructed and exposed to natural weathering for 18 months. The individual plaster panels are sampled biannually and examined for mineralogical alterations. Additionally, the rainwater runoff from the plaster panels is collected and regularly analyzed. Parallel to the outdoor test setup, laboratory experiments are conducted to investigate the influence of cement on olivine weathering. With the experimental results and data from the manufacturing process, a comprehensive sustainability assessment for the olivine-based facade plaster will ultimately be created.

Services

Laboratory investigations into "enhanced weathering" processes.

Current Results

Irmai, A., Berndsen, M., Baese, R., and Alms, K.: Enhanced weathering in building materials: Capturing CO2 with olivine-based façade plaster, EGU General Assembly 2024, Vienna, Austria, 14–19 Apr 2024, EGU24-15573, https://doi.org/10.5194/egusphere-egu24-15573, 2024. (with corresponding link: Abstract EGU24-15573 copernicus.org)