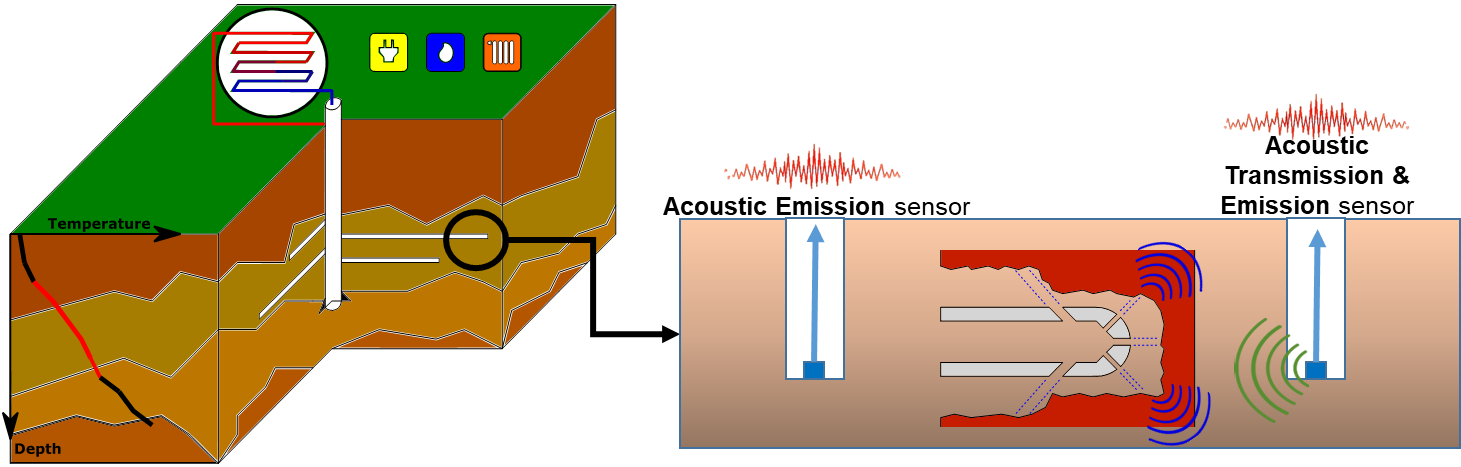

CAGE is a demonstration project for new drilling, expansion, and stimulation technologies that offer increased control and security in the development and application of geothermal reservoirs in carbonate rocks. This will ultimately reduce investment and usage costs, while also increasing the geothermal energy output. Based on physical projects in the Netherlands with the project partners, a range of different technologies (e.g. borehole expansion using composite casing) are and will continue to be implemented and evaluated. For now, the carbonate rocks can range up to a depth of 1.5 km. As part of the contributions of Germany/IEG to CAGE, qualitative monitoring is being provided for technical drilling processes such as radial jetting for drilling to stimulate, i.e. increase, the “flow rate”. This combination of technologies could significantly improve the quality and efficiency of jetting-based stimulation processes.

CAGE

Composite casing and the Acceleration of Geothermal

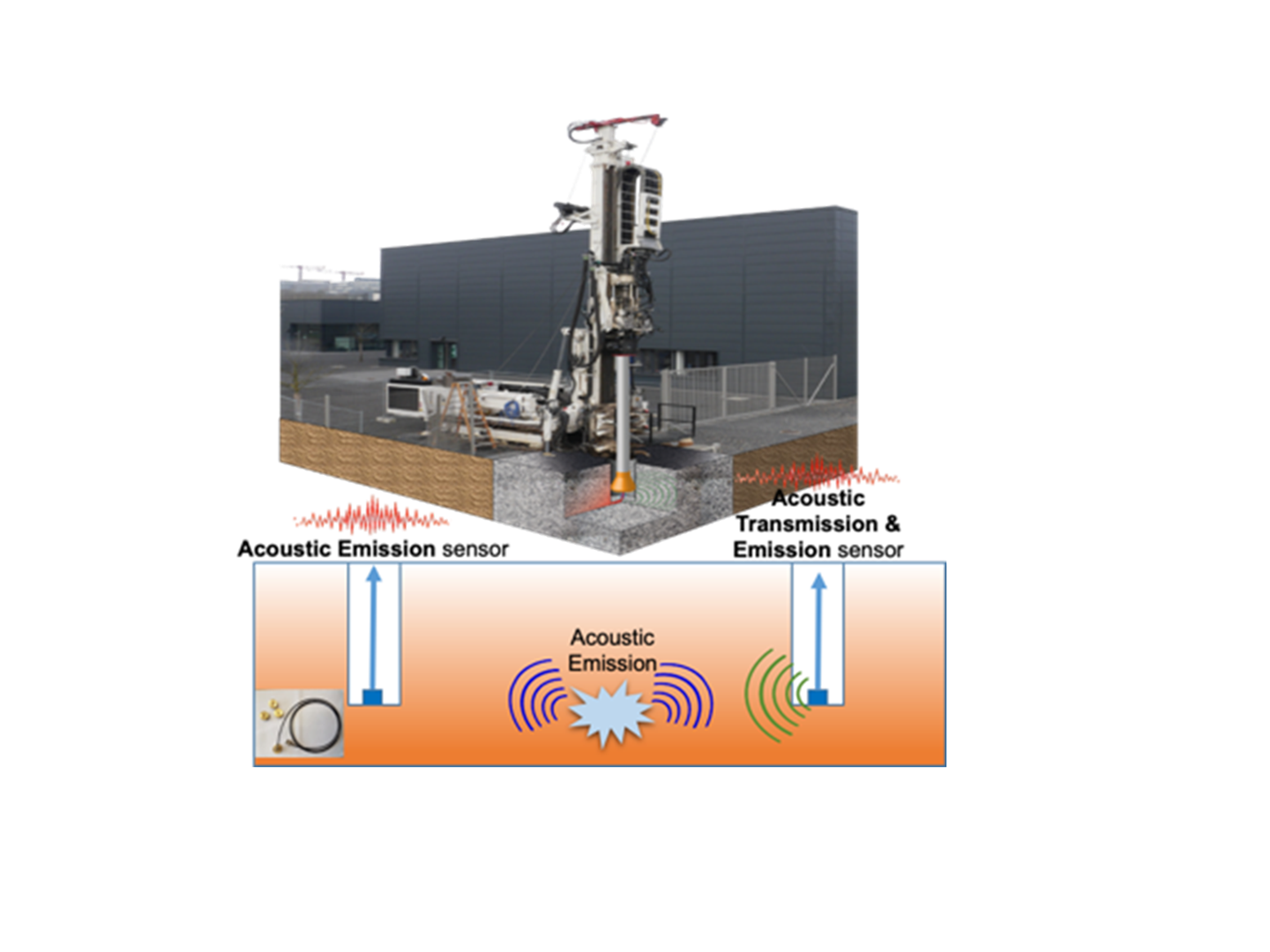

CAGE implements the Multi Sensor Acoustic Parameter Analysis (MOUSE) technology by GZB/Fraunhofer, which is a first in the history of rock jetting/drilling. This involves equipping the current jetting process used by the industry and all of its element with sensors and monitoring systems, from the surface right down to the reservoir entry point. The MOUSE system then allows conclusions to be drawn about the jetting process and changes within the reservoir, which at the moment primarily concerns carbonate rocks. From this, the MWjet Log can be developed and used to monitor the jetting process in the rock. Any changes or anomalies in the reservoir, such as karst zones, faults, porosities, cracks, fractures, and so on can be detected. These zones need to be precisely identified, reached, and drilled in order to connect them to the main borehole and exploit them hydraulically.

Funding