For harvesting geothermal energy and other subsurface utilization, the borehole, or well, serves as the central connection between the surface and the underground reservoir. Well enhancement or stimulation, commonly used in hydrocarbon (EOR) type reservoirs, is increasingly applied to geothermal, thermal or gas/hydrogen storage, mining, extraction of rare metals, and similar applications. These enhancements aim to primarily improve the hydraulic connection between the production borehole and the surrounding target reservoir. This typically boosts overall productivity from the well and in specific production zones by, for example, creating micro-sized laterals, thereby increasing free surface area and hydraulic conductivity.

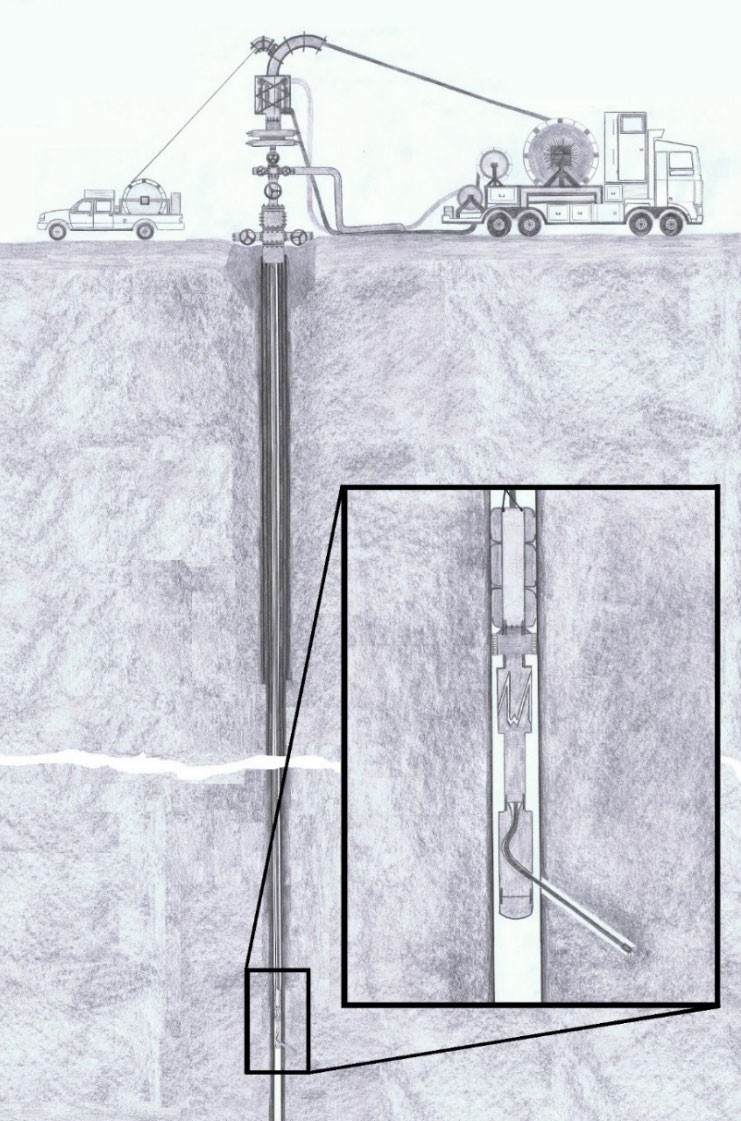

The ROCKET project encompasses the design and development of an innovative, purpose-built underground BHA, including its deflection technique, horizontal positioning/rotation capabilities, and an axial locking system, all based solely on wireline or coiled tubing operations. Coiled tubing-based micro-drilling techniques, such as Radial Jet Drilling (RJD), Micro Turbine Drilling (MTD), and compact percussion drilling, are increasingly being utilized to enhance the productivity and efficiency of a wellbore and its surrounding reservoir. These micro-drilling technologies help eliminate permeability barriers within the near-wellbore zone and beyond in all types of geological formations, thereby increasing overall resource utilization. A key advantage of ROCKET and its associated micro-type coiled tubing drilling techniques is the simple, fast, and low-effort deployment, avoiding large, costly workover rigs and expensive directional drilling techniques. This enables efficient, cost-effective horizontal laterals, albeit with limited diameters and lengths, but with relatively high deflection angles and efficiency.

Objectives

The main goal of the ROCKET project is to develop an entirely new, purpose-built underground BHA system that significantly simplifies the use of all available coiled tubing-based micro-drilling technologies in geothermal and other reservoirs while making them more efficient. By installing all BHA-relevant components solely via coiled tubing and/or wireline systems, lengthy, complex, and expensive installations of jointed casings or pipes are avoided. This new type of BHA will also enable more “automated” wireline or coiled tubing-operated orientation in the borehole, allowing for quicker execution of multiple horizontal kick-offs without the need for tripping. Furthermore, future monitoring of such micro-drilling processes will be easily facilitated through a possible direct data connection, even "while drilling." This will help further increase drilling efficiency and reservoir intervention. Such QA/QC-type monitoring of today's micro-drilling efforts is currently not possible but is urgently needed. At best, some approaches are available for the so-called "post-run" procedure after drilling.